Until the middle of the 20th century millstones - a device for manual grinding of grain - were a necessary device in almost every peasant yard since the price for grinding at the mill was high. They often stood in the hallway, sometimes in a hut or shed.

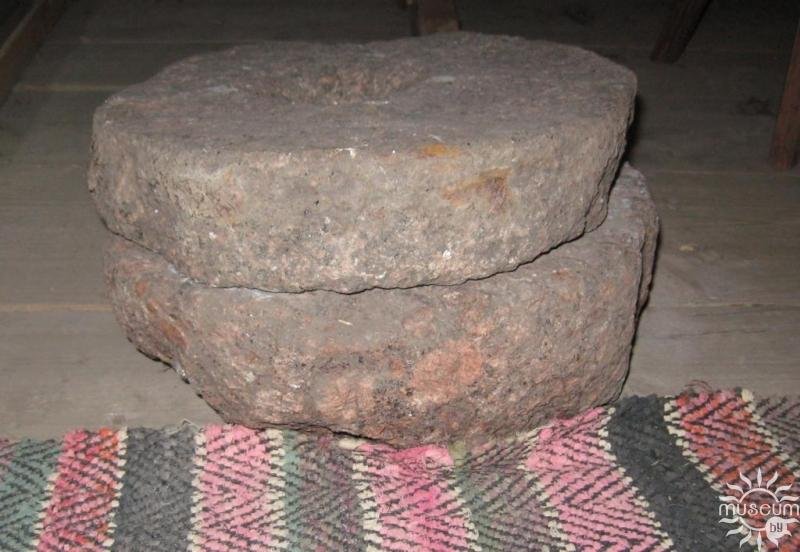

Hand-made millstones presented in the museum’s exposition are a random find on the territory of the former Lower Castle. They consist of two discoid stones. The lower fixed disc has a slightly convex work surface. The top millstone (runner) is more concave, with a small hole in the middle for filling the grain. Getting between the stones, the grain is crushed and ground into flour. Notches are made on the lower disk from the center to the edge for better grinding. The grooves of the notches served as original paths along which the flour was poured from the millstones. For more convenient collection of flour millstones were placed in a special wooden box.

The best material for the manufacture of millstones served as a special stone - hard sandstone, called a millstone, or limestone containing fossils.